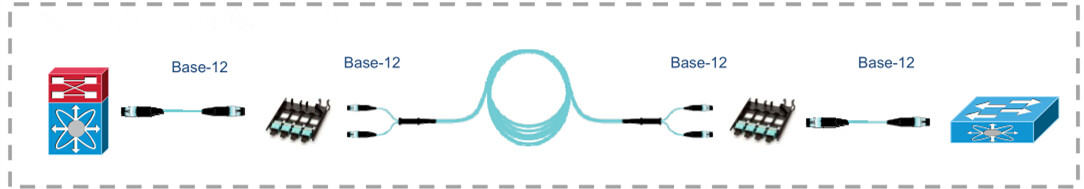

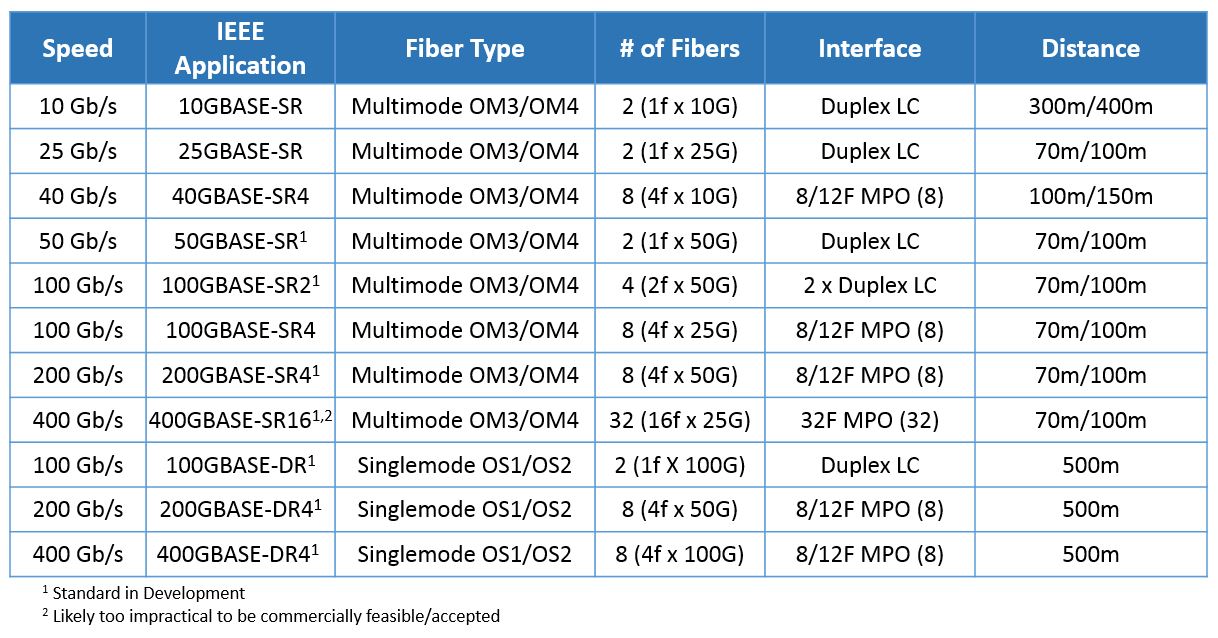

With

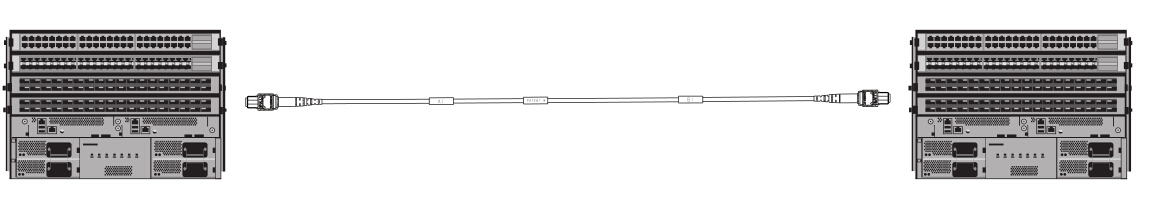

data centers moving to 40G/100G, MPO fiber cables are extensively

deployed. To ensure the reliable and efficient performance of the MPO

cables, it is critical to clean the MPO connectors before mating to

other equipment as contaminated connectors would lead to degraded

performance and costly but preventable failures. There are two ways to

clean MTP/MPO connectors. One is to use cassette cleaner, while the

other is to use one-click cleaner. This post will talk about these two

types of cleaning methods for MTP/MPO connectors.

One-Click Cleaner vs. Cassette Cleaner: Using Rules

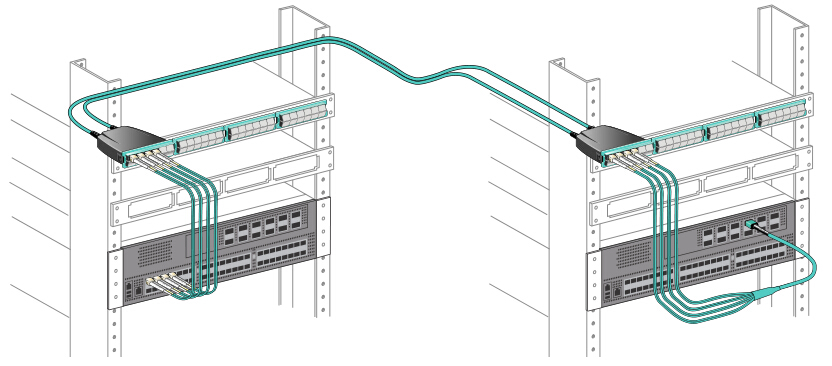

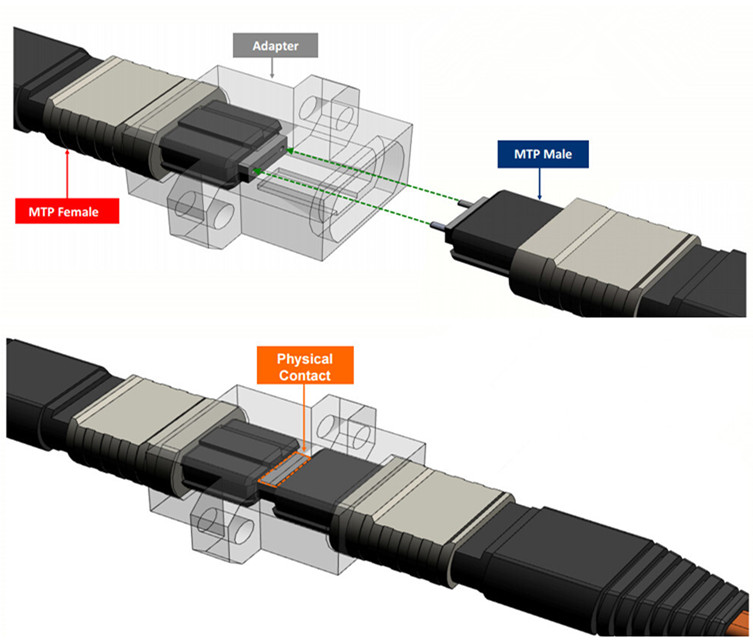

The

one-click cleaner for MTP/MPO connectors is a cost-effective tool for

cleaning fiber end-faces without the use of alcohol. It can clean both

exposed jumper ends and connectors in adapters with one-push action. A

cassette cleaner contains a refillable lint free reel of cloth that is

moved after each cleaning, always presenting a clean surface. It is

applicable primarily for cleaning connectors with one-wipe action in dry

cleaning without any alcohol and other harsh chemicals.

One-Click Cleaner vs. Cassette Cleaner: Cleaning Procedures

For

both the two cleaning methods, please always inspect before cleaning.

If the connector is already clean, there is no need to clean it.

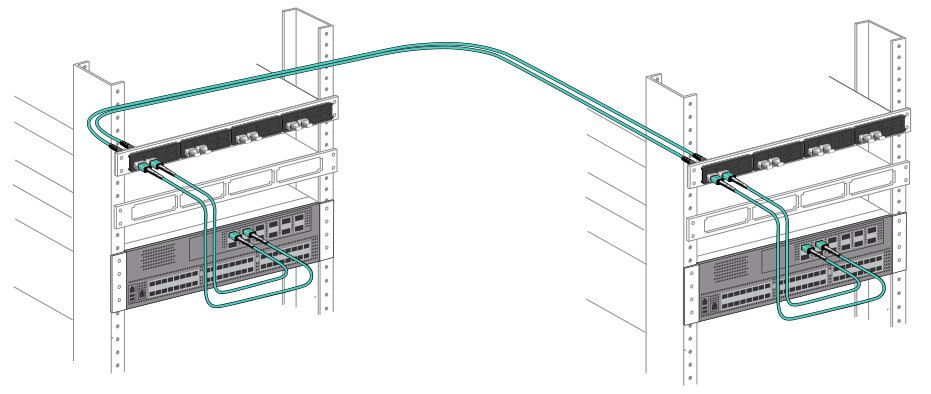

Cleaning Procedures of One-Click Cleaner (For Connectors in Adapters)

- Pull off the guide cap.

- Insert the cleaning tool into the bulkhead and turn the cleaning wheel backwards until click two times.

Cleaning Procedures of One-Click Cleaner (For Exposed Connectors)

- Carefully pull out the guide cap cover.

- Insert the patch cord into the cleaning tool, apply slight pressure and turn the cleaning wheel backward until click two times.

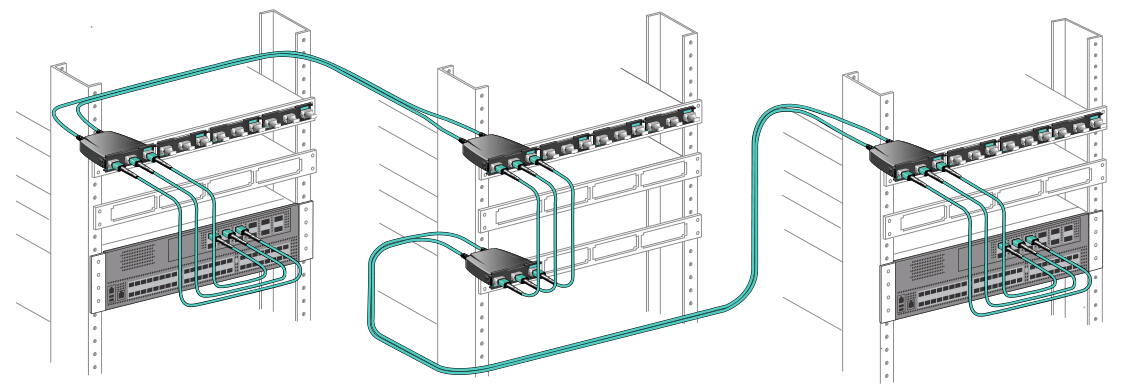

Cleaning Procedures of Cassette Cleaner

- Remove connector dust cover.

- Select the appropriate cleaner for male/female.

- For female MTP/MPO connectors, use the cleaning brush and fluid to remove any debris from the pin holes.

- Depress the lever so that a fresh area of cleaning cloth is exposed.

- Position the ferrule against the cloth so that the fibers are in contact with the cleaning material. In the case of angled connectors, the ferrule will need to be adjusted accordingly.

- Wipe the connector in the direction shown on the cassette.

- Release the grip to seal off the cleaning cloth.

- Let the ferrule air-dry before inspecting with a 200xmicroscope.

- If still contaminated repeat all steps once again.

- Ensure that the connector does not touch any hard surfaces.

Note: Do not move connector back and forth. Connector is to be moved in only the direction of the arrows on the cleaner.

One-Click Cleaner vs. Cassette Cleaner: Which to Choose?

From

what have described above, we can summarize that one-click cleaner can

be used for connectors in adapters and exposed connectors, while

cassette cleaner is only applicable for exposed connectors. Moreover,

the one-click cleaner is capable of cleaning ferrules with or without

guide pins. But for cassette cleaner, you should choose the correct type

to clean male or female connectors. In my opinion, one-click cleaner is

more convenient. Among the two, which is your choice?