When talking about 40G cabling, MPO cable

is the most common choice for data center managers to use. Today, I’d

like to talk about three types of MTP cabling options for 40G parallel

connectivity. The first type is to deploy MPO 12 cable and ignore the

unused four fibers. And the other two types are using conversion module

or conversion harness to convert two 12-fiber links into three 8-fiber

links. So the three cabling options—no conversion vs. conversion module

vs. conversion harness: which to use for 40G parallel solution?

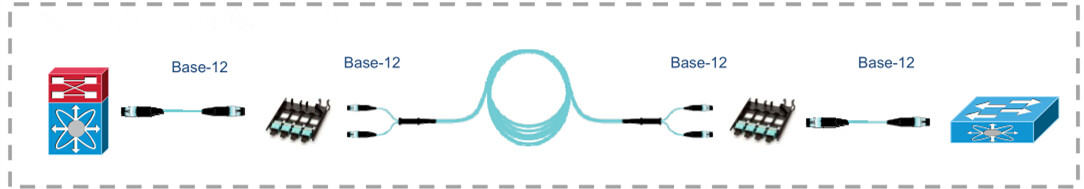

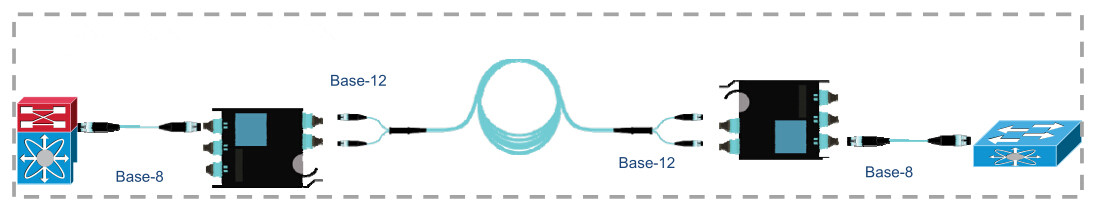

Solution 1: No Conversion

For

no conversion scenario, 12-fiber based MTP trunk cables are deployed in

the whole 40G connectivity. But in this situation, 33% fiber is not

used. And there will be additional cost associated with the purchase of

additional fiber. Moreover, the whole system includes unused fibers.

Figure 1: no conversion used, the whole link uses base-12 MTP/MPO cable

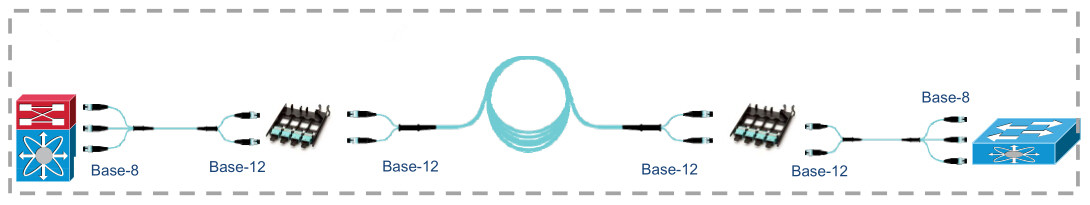

Solution 2: Conversion Module

With

using conversion module, it can convert the unused fibers into usable

fiber links. For every two 12-fiber MTP connectors in the backbone

cable, you can create three 8-fiber links. Although there will be

additional cost for the additional MTP connectivity, it can be offset by

the cost savings from 100% fiber utilization in the structured cabling.

When reusing existing deployed MTP cabling, great value will be gained

if using conversion module to use all previously deployed fiber, and you

eliminate the cost of having to deploy additional cabling.

Figure 2: use conversion module to convert two 12-fiber links into three 8-fiber links

Solution 3: Conversion Harness

This

scenario uses standard MTP patch panels and 2x3 MTP conversion harness.

It does not add any connectivity to the link and full fiber utilization

is achieved. Although it seems attractive, it involves considerable

cabling challenges. For instance, if you only need two 40G connections

to the equipment, what do you do with the third 8-fiber MTP connection?

Or what if the 40G ports are in different chassis blades or completely

different chassis switches? The result will be long assemblies, which

will be difficult to manage in an organized way. For this reason, this

kind of solution is expected to be the least desirable and so the least

deployed method.

Figure 3: use conversion harness to convert two 12-fiber links into three 8-fiber links

No Conversion vs. Conversion Module vs. Conversion Harness

For

the three types of connectivity solutions, the “No Conversion”

solution, using traditional 12-fiber MTP connectivity and ignoring

unused fibers, has the advantage of simplicity and lowest link

attenuation. And as it does not use 33% of the installed fiber, it then

requires more cable raceway congestion.

The

“Conversion Module” solution, converting two 12-fiber links into three

8-fiber links through a conversion patch panel, uses all backbone fibers

and creates a clean, manageable patch panel with off-the-shelf

components. But it would lead to additional connectivity costs and

attenuation associated with the conversion device.

The

“Conversion Harness” solution, converting two 12-fiber links into three

8-fiber links through a conversion harness and standard MTP patch

panel, uses all backbone fibers with additional connectivity. But it

would create cabling challenges with dangling connectors and

non-optimized-length patch cords that require customization.

Generally,

the implementation of the conversion module solution is recommended,

especially if you are using previously installed MTP trunks. Conversion

module solution allows 100% fiber utilization while maintaining any port

to any port patching. And if you are installing new cabling, then you

can consider the no conversion solution, assuming that the cable raceway

is not a concern. The conversion harness solution is typically deployed

only in specific applications, such as at the ToR switch, where 40G

ports are in a close cluster and patching between blades in a chassis

switch is not required.

Conclusion

From

what have described above, have you had a better understanding of these

three types of 40G cabling solution? Each type has their own advantages

and disadvantages. For those three solution choices—no conversion vs.

conversion module vs. conversion harness: which is your choice for 40G

parallel solution?

Originally published: www.fiberopticshare.com/no-conversion-vs-conversion-module-vs-conversion-harness.html