Growing

demand for high speed internet drives the new access technologies which

enable experiencing true broadband. This leads telecommunication

operators to seriously consider the high volume roll-out of optical

fiber based access networks. In order to allow faster connections, the

optical fiber gets closer and closer to the subscriber. Then FTTH (Fiber

To The Home) appears the most suitable choice for a long term objective

because it will be easier to increase the bandwidth in the future if

the clients are wholly served by optical fibers. FTTH is a future-proof

solution for providing broadband services.

Passive

optical network (PON) based FTTH access network is a

point-to-multipoint, fiber to the premises network architecture in which

unpowered optical splitters are used to enable a single optical fiber

to serve multiple premises, typically 32-128. The GPON FTTH access

network is highly emphasized in this article.

Components of GPON FTTH Access Network

Taking

advantages of WDM (wavelength division multiplexing), PON uses one

wavelength for downstream traffic and another for upstream traffic on a

single fiber. The OLT (Optical Line Terminal) is the main element of the

network. Placed in the Local Exchange, OLT is the engine that drives

FTTH system. OLT performs the function of traffic scheduling, buffer

control and bandwidth allocation. The optical splitter

splits the power of the signal and enables sharing of each fiber by

many users. ONT (Optical Network Terminal) is deployed at customer’s

premises and connected to the OLT through optical fiber and no active

elements are present in the link.

GPON FTTH Access Network Architecture

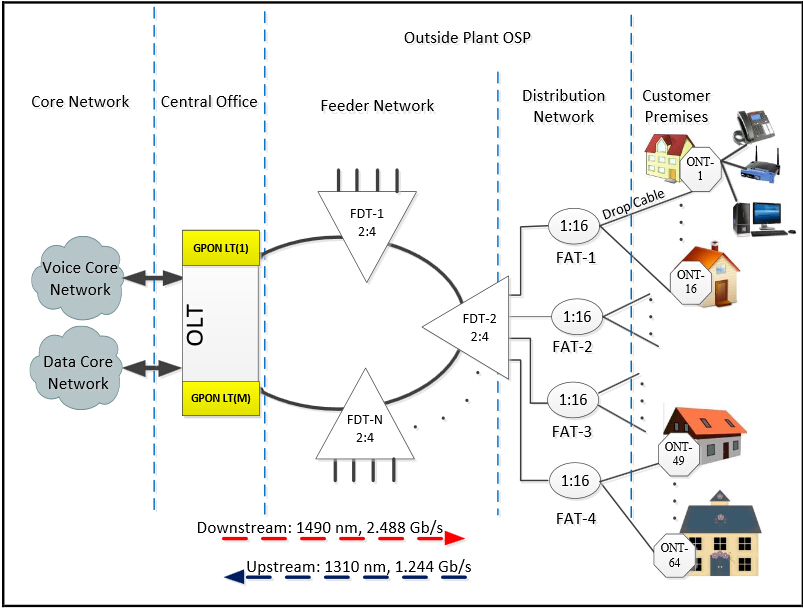

With

a tree topology, GPON is able to maximize the coverage with minimum

network splits, thus reducing optical power. A FTTH access network

comprises five areas, namely a core network area, a central office area,

a feeder area, a distribution area and a user area as shown in the

following diagram.

The

core network includes the ISP (internet service provider) equipment,

PSTN (packet switched or the legacy circuit switched) and cable TV

provider equipment. The main function of the central office is to host

the OLT

and ODF and provide the necessary powering. The feeder area extends

from ODF (optical distribution frames) in the CO (central office) to the

distribution points. Distribution cable connects level-1 splitter with

level-2 splitter. Level-2 splitter is usually hosted in a pole mounted

box placed at the entrance of the neighborhood. In the user area, drop

cables are used to connect the level-2 splitter to the subscriber

premises.

Traffic Flow in GPON FTTH Access Network

The

data is transmitted from OLT to ONT in downstream as a broadcast manner

and as a time division multiplexing (TDM) in upstream. The wavelength

of the downstream data is 1490 nm. Core network data services

transported over the optical network reaches the OLT and then

distributed to the ONTs through the FTTH network by dint of power

splitting. Every home receives the packets intended to it through its

ONT. The upstream represents the data transmission from the ONT to OLT

and the wavelength is 1310 nm. If the signals from different ONTs arrive

at the splitter input at the same time and at the wavelength 1310 nm,

it will lead to superposition of different ONT

signals when it reaches OLT. Thus TDMA is adopted to avoid the

interference of signals from ONTs. In TDMA time slots will be provided

to each user on demand for transmission of their packets. At the optical

splitter packets arrive in order and they are combined and transmitted

to OLT.

Conclusion

This

paper presents the components, architecture, and traffic flow in GPON

FTTH access network. The content may not be detailed, but GPON FTTH

network architecture is indeed reliable, scalable, and secure. It is a

passive network, so there are no active components from the CO to the

end user, which dramatically minimizes the network maintenance cost and

requirements. It is a future-proof architecture.

Article source: www.fiberopticshare.com/ftth-access-network-based-on-gpon-2.html