When

a connector is installed on the fiber end, loss will be incurred. Some

light loss would be reflected back directly down the fiber towards the

light source that generated it. These back reflections, or Optical

Return Loss (ORL) will damage the laser light sources and also disrupt

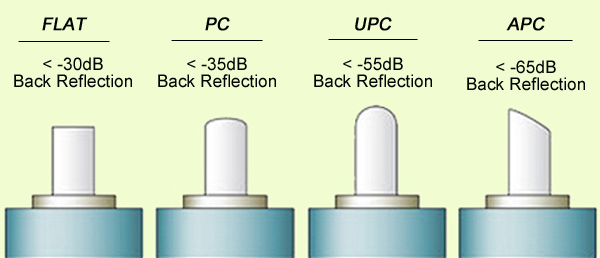

the transmitted signal. Fiber connectors with different polishing types

have different back reflections (see the picture below). With the

development of technology, four polishing types are available:

flat-surface, Physical Contact (PC), Ultra Physical Contact (UPC), and

Angled Physical Contact (APC). How one evolves into another? This

article will tell the answer.

Flat Fiber Connector

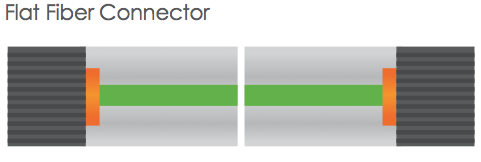

The

original fiber connector is a flat-surface connection, or a flat fiber

connector. The primary issue of it is that a small air gap between the

two ferrules is naturally left when mated. This is partly because the

relatively large end-face of the connector allows for numerous slight

but significant imperfections to gather on the surface. The flat fiber

connector is not suitable for single-mode fiber cables with a 9µm core

size, thus it is essential to evolve into Physical Contact (PC)

connectors.

PC Fiber Connector

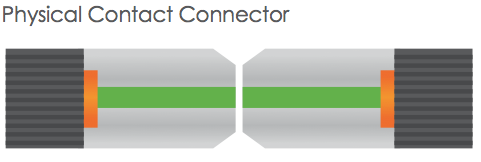

The

Physical Contact is polished with a slight spherical design to reduce

the overall size of the end-face, which helps to decrease the air gap

issue faced by Flat Fiber connectors. It results in lower Optical Return

Loss (ORL) with less light being sent back towards the power source.

UPC Fiber Connector

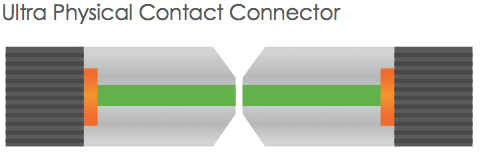

Building

on the convex end-face attributes of the PC, but utilizing an extended

polishing method creates an even finer fiber surface finish: Ultra

Physical Contact (UPC) connector. It has a lower back reflection (ORL)

than a standard PC connector and allows more reliable signals in digital

TV, telephony and data systems. UPC fiber connector could be used with

both single-mode fiber and multimode fiber. Usually the UPC single-mode

fiber connector is blue, but the UPC multimode fiber connector is beige.

(Note: 10G UPC multimode fiber connector is aqua.)

PC

and UPC connectors do have a low insertion loss, but the back

reflection (ORL) depends on the the surface finish of the fiber. The

finer the fiber grain structure, the lower the back reflection. When PC

and UPC connectors are continually mated and unmated, the back

reflection will begin to degrade. So there is a need for a connector

with low back reflection and it could sustain repeated matings/unmatings

without ORL degradation.

APC Fiber Connector

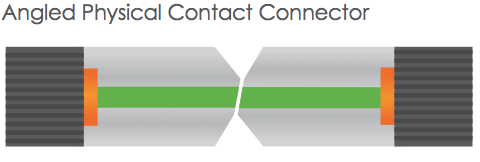

The

end faces of Angled Physical Contact connectors are still curved but

are angled at an industry standard eight degrees, which allows for even

tighter connections and smaller end-face radii. Combined with that, any

light that is redirected back towards the source is actually reflected

out into the fiber cladding, again by the virtue of the 8°angled

end-face. APC connector back reflection does not degrade with repeated

matings/unmatings. APC fiber connector can only be used with single-mode

fiber and it is green.

It is clear that all of the connector end-face options mentioned above take a place in the market. And it is hard to claim that one connector beats the others when your specification needs to consider cost and simplicity not just optical performance. Your particular need decides which one to choose. For those applications calling for high precision optical fiber signaling, APC should be the first consideration, but less sensitive digital systems will perform equally well using UPC. For various connector options, please visit FS.COM.

Article source: www.fiber-optic-components.com/evolution-of-flat-pc-upc-and-apc-fiber-connectors.html

没有评论:

发表评论