Fiber optic cable is a very thin glass strand through which a pulse of light is transmitted. Nowadays, fiber optic cable

is a desirable cable medium due to its immunity to electromagnetic

interference (EMI) and radio frequency interference (RFI). It can

transport optical signals for significant distances, whether in local

area, wide area, or in metropolitan area. This article will tell some

information about fiber optic cables and aim at providing a guideline on

choosing the right fiber optic cable.

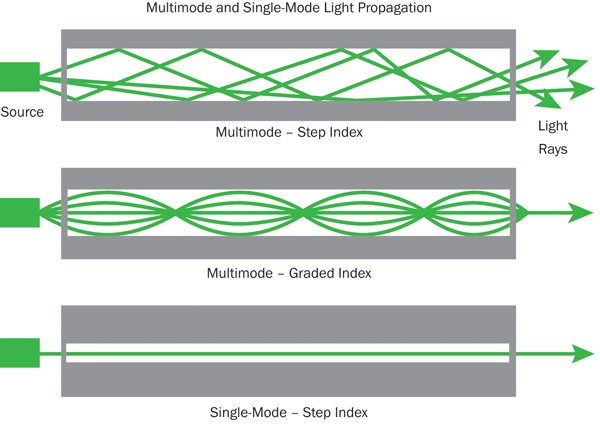

Single-mode or Multimode Fiber Optic Cable

Fiber

optic cable can be divided into single-mode fiber cable and multimode

fiber cable. Single-mode optical fiber generally has a core diameter of 9

µm and requires laser technology for sending and receiving data. It can

carry a signal for miles, which makes it ideal for telephone and cable

television providers. As the name suggests, multimode fiber permits the

signal to travel in multiple modes, or pathways, along the inside of the

glass strand or core. It is available with fiber core diameters of 62.5

µm or 50 µm. Although the core sizes of single-mode fiber and multimode

fiber differ, both fiber types end up with an outer diameter of about

250 µm. The key differences between the two kinds of fiber optic cables

have been illustrated more clearly in another article—Single-mode Fiber vs. Multimode Fiber: Which to Choose?

Indoor Cables or Outdoor Cables

The

major difference between indoor cables and outdoor cables is water

blocking. Any conduit is someday likely to get moisture in it. Outdoor

cables are designed to protect the fibers from years of exposure to

moisture. Indoor cables are what we call “tight-buffered” cables, where

the glass fiber has a primary coating and secondary buffer coatings that

enlarge each fiber to 900 microns—about 1mm or 1/25-inch, to make fiber

easier to work with.

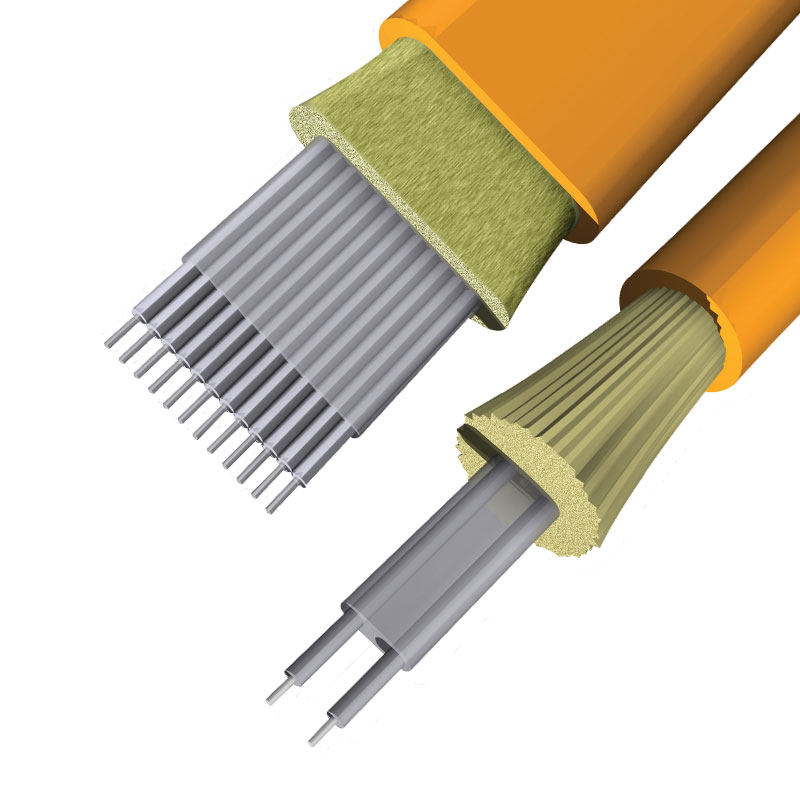

Indoor Cables

Usually, indoor cables

include simplex and zipcord, distribution cables and breakout cables.

Simplex fiber optic cables are one fiber, tight-buffered (coated with a

900 micron buffer over the primary buffer coating) with Kevlar (aramid

fiber) strength members and jacketed for indoor use. The jacket is

typically 3mm (1/8 in.) diameter. Zipcord is simply two of these jointed

with a thin web. It’s used mostly for patch cord and backplane

applications, but zipcord can also be used for desktop connections.

Distribution

cables contain several tight-buffered fibers bundled under the same

jacket with Kevlar strength members and sometimes fiberglass rob

reinforcement to stiffen the cable and prevent kinking. These cables are

small in size, and used for short, dry conduit runs, riser and plenum

applications. The fibers are double buffered and can be directly

terminated, but because their fibers are not individually reinforced,

these cables need to be broken out with a “breakout box” or terminated

inside a patch panel or junction box. The distribution cable is the most

popular cable for indoor use.

Breakout

cables are made of several simplex cables bundled together inside a

common jacket for convenience in pulling and ruggedness. This is a

strong, rugged design, but is larger and more expensive than the

distribution cables. They are suitable for conduit runs, riser and

plenum applications, and ideal for industrial applications where

ruggedness is important or in a location where only one or two pieces of

equipment need to be connected.

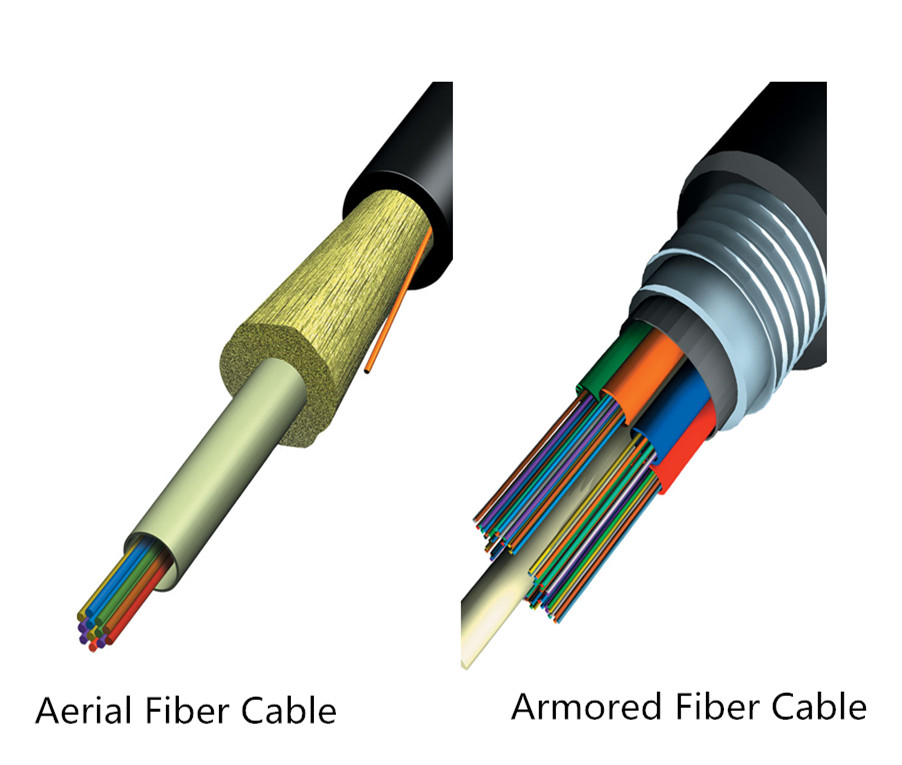

Outdoor Cables

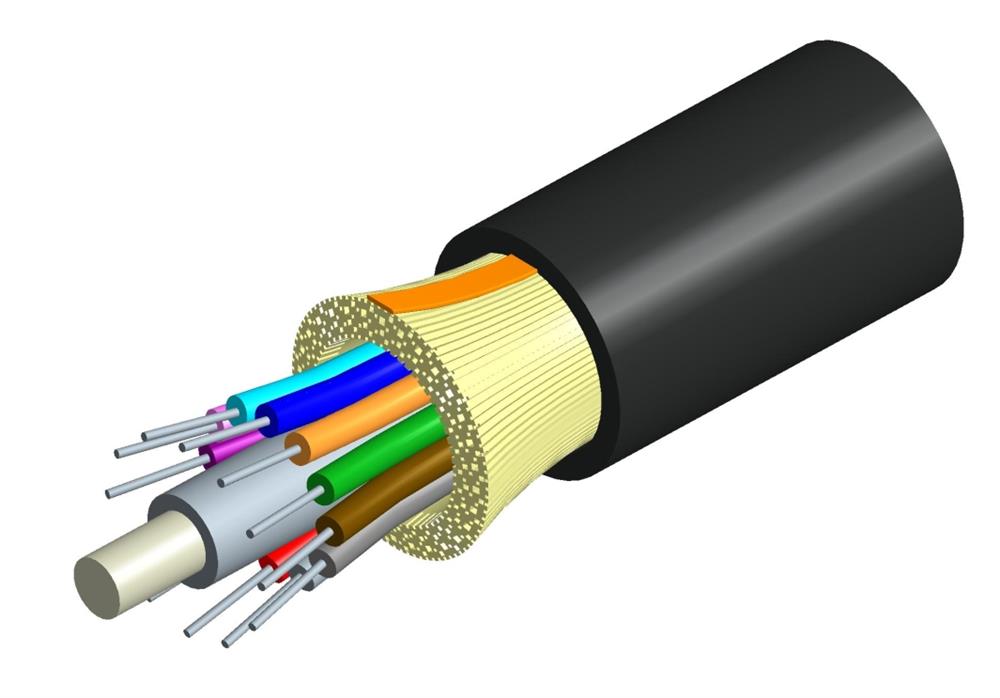

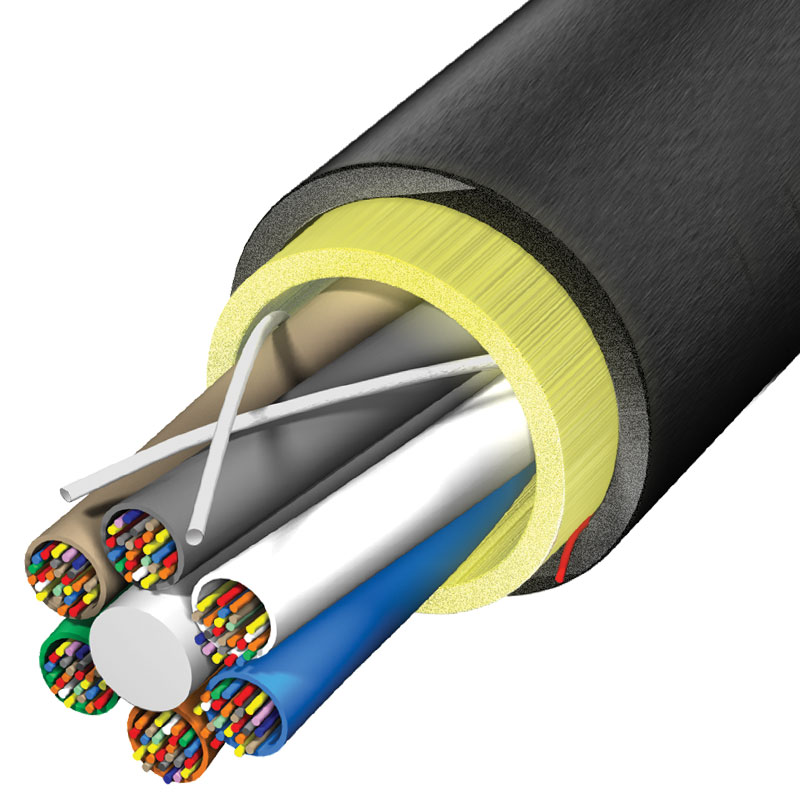

Fiber

optic cables in outdoor applications require more protection from water

ingress, vermin and other conditions encountered underground. Outdoor cables

need increased strength for greater pulling distances. Generally, fiber

optic cables installed in outdoor applications contain loose tube fiber

optic cable, ribbon fiber optic cable, armored fiber optic cable and

aerial fiber optic cable.

Loose

tube fiber optic cables are composed of several fibers together inside a

small plastic tube, which are in turn wound around a central strength

member and jacketed, providing a small, high fiber count cable. They are

suitable for outside plant trunking applications because they can be

made with loose tubes filled with gel or water absorbent powder to

prevent harm to the fibers from water. Since the fibers have only a thin

buffer coating, they must be carefully handled and protected to prevent

damage. They can be used in conduits, strung overhead or buried

directly into the ground.

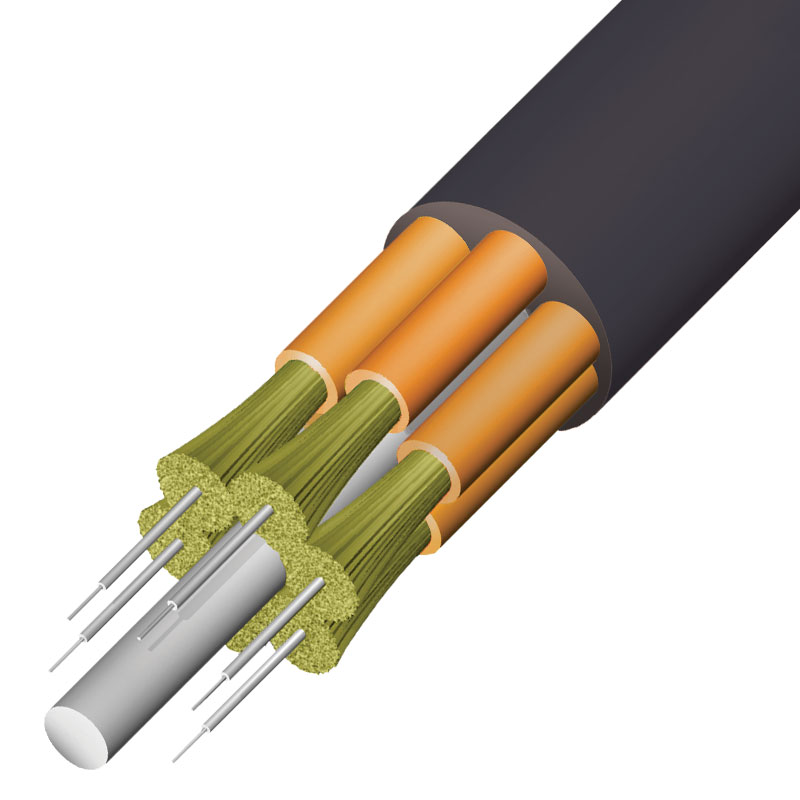

Ribbon

fiber optic cables offer the highest packing density as all the fibers

are laid out in rows, typically of 12 fibers, and laid on top of each

other. In this way, 144 fibers only have a cross section of about 1/4

inch or 6mm. Some cable designs use a slotted core with up to 6 of these

144 fiber ribbon assemblies for 864 fibers in one cable. Because they

are outside plant cables, they are gel-filled for water blocking.

Armored

fiber optic cables are installed by direct burial in areas where

rodents are a problem. Usually they have metal armored between two

jackets to prevent rodent penetration. This means the cable is

conductive, so it must be grounded properly. It is best to choose

armored fiber optic cable when use cable directly buried outdoor. Aerial

fiber optic cables can be lashed to a messenger or another cable

(common in CATV) or have metal or aramid strength members to make them

self-supporting. Aerial cables are for outside installation on poles.

Cable Jackets: PVC (OFNR), OFNP, or LSZH

Cable

jackets can provide strength, integrity and overall protection of the

fiber member. PVC is widely used as a cable jacket for many

applications—computers, communications, low-voltage wiring, etc. PVC can

potentially be dangerous in a fire situation, releasing heavy smoke and

hydrogen chloride gas, which can be irritating to humans and corrosive

to electronic devices. OFNP, or plenum jackets, are suitable for use in

plenum environments such as drop-ceilings or raised floors. Many data

centers and server rooms have requirements for plenum-rated cables. LSZH

is a jacket made from special compounds which give off very little

smoke and no toxic halogenic compounds when burned.

Summary

When

choosing the fiber optic cables, please always remember the elements

mentioned in this article. Only make clear all these aspects can you

select the fiber optic cable that most suits your applications. If you

are still confused about which one to choose, you can visit www.fs.com

or contact sales@fs.com to seek help as lots of professional advice can

be given by FS team.

Originally published: www.fiberopticshare.com/guide-choosing-right-fiber-optic-cable.html