With

the increasing demands for higher speeds, and greater scalability, many

service provider networking environments and enterprise data centers

are undergoing an infrastructure transformation to get higher levels of

performance and reliability. As speed and performance needs increase,

optical transceivers have become an integral part of overall system

design. And then 40G and 100G fiber optic transceiver have become

preferable choices for more and more data centers as 1G and 10G cannot

meet the needs of the bandwidth-hungry applications. Adopting 100G

transceivers not only accelerates data flow throughout your data center

or enterprise, but also provides CAPEX (capital expenditures), OPEX

(operating expenditures) and time savings. This article focuses on the

hot 100G transceiver modules for data centers.

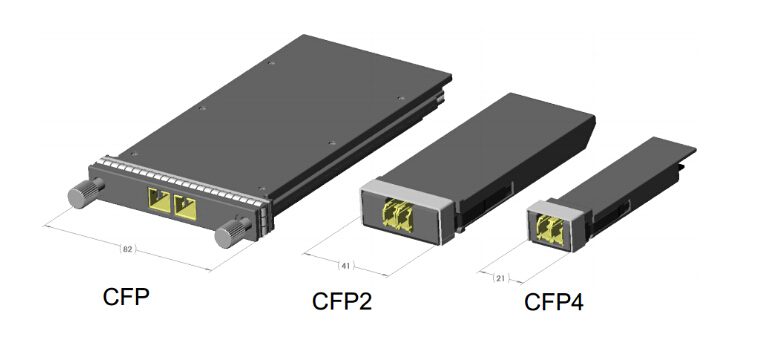

100G CFP/CFP2/CFP4

When

the IEEE finished the first 100G standard for Ethernet networks, the

transceiver industry launched an alphabet soup of form factors. The CFP

emerged first, "C" for 100, and FP for "Form factor, Pluggable". The CFP

transceiver is specified by MSA between competing manufacturers. The

CFP was designed after SFP interface, but is significantly larger to

support 100 Gbit/s. While the electrical connection of a CFP uses 10 x

10 Gbit/s lanes in each direction (RX, TX), the optical connection can

support both 10 x 10 Gbit/s and 4 x 25 Gbit/s variants of 100 Gbit/s

interconnects.

With

improvements in technology allowing higher performance and higher

density, the development of the CFP2 and CFP4 specifications appeared.

While electrical similar, the CFP2

and CFP4 specify a form-factor of 1/2 and 1/4 respectively in size of

the CFP. The three modules are not interchangeable, but would be

inter-operable at the optical interface with appropriate connectors.

100G QSFP28 Transceiver

The

QSFP28 is the exact same footprint as the 40G QSFP+. The "Q" is for

"Quad". Just as the 40G QSFP+ is implemented using four 10 Gbit/s lanes,

the 100G QSFP28 is implemented with four 25 Gbit/s lanes. With an

upgraded electrical interface to support signaling up to 28 Gbit/s

signals, the 100G QSFP28 makes it as easy to deploy 100G networks as 10G

networks. When compared to any of the other alternatives, the 100G

QSFP28 increases density and decreases power and price per bit. So it is

fast becoming the universal data center form factor for the following

reasons.

The

QSFP28 increases front-panel density by 250% over QSFP+. The form

factor is the same and the maximum number of ports is the same, but the

lane speeds are increased from 10 Gbit/s to 25 Gbit/s. The increase in

panel density is even more dramatic when compared to some other 100

Gbit/s form factor: 450% versus the CFP2.

The

QSFP28 transceivers can be based on either VCSELs (for shorter

distances on multimode fiber) or silicon photonics (for longer distances

on single-mode fiber). The advent of silicon photonics enables QSFP28

transceivers to support any data center reach up to 2 km or more.

Silicon photonics provides a high degree of integration.

Fiberstore 100G Transceiver Solution

As

a professional manufacturer and supplier in optical communication

industry, Fiberstore provides a complete range of 100G fiber optic

transceivers to meet the potential requirements. We have already

prepared the stock of the CFP and CFP2 modules, which can be shipped

immediately after ordering. For 100G QSFP28 transceivers, we have 100GBASE-SR4 QSFP28

and 100GBASE-LR4 QSFP28 transceivers. With our serious cost control,

the prices of all our 100G fiber optic transceivers are much more

affordable than the similar products in the market. Furthermore, with

the mature coding technology, they can be compatible with many major

brands. For more details, please visit www.fs.com or contact over

sales@fs.com.

Article source: www.fiberopticshare.com/hot-100g-fiber-optic-transceivers-for-data-center.html

Article source: www.fiberopticshare.com/hot-100g-fiber-optic-transceivers-for-data-center.html