Ethernet

technology has continually evolved in order to meet the never-ending

requirement for faster rates of data transmission. The demand for faster

application speeds has also spurred technological evolution on data

carrying techniques. As such, copper and fiber transmission standards

have progressed, providing greater bandwidth for transporting data over

Ethernet architectures with reduced cost and complexity. This article

highlights the cabling solutions for 1 Gigabit Ethernet and 10 Gigabit

Ethernet.

1 Gigabit Ethernet Cabling

For 1 Gigabit Ethernet cabling, both fiber and copper cable connections are available.

Fiber Cabling

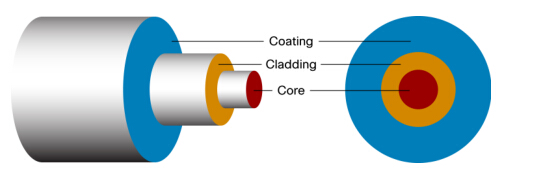

The

optical fiber cables are usually used for longer connections. Optical

fiber connections are constructed with a combination of a transceiver,

which receives digital signals from the Ethernet device (switch or

adapter card) and converts them to optical signals for transmission over

the fiber. The most widely used transceiver for 1 Gigabit Ethernet is

SFP (small form factor pluggable). For instance, the Cisco GLC-LH-SMD

1000BASE-LX/LH SFP can support transmission distance up to 10

kilometers.

The

difference in cable choices comes from the distance limitations

encountered with the various types of optical transmission. Short range

and long range are the two different commonly available types. Short

range supports connections of up to 550 meters, while long range

supports connections of up to 10 kilometers. Multimode fiber cables are

typically used for short range transmission and single-mode fiber cables

are used for long range transmission.

The

final consideration on the fiber cable is the connector type. The main

differences among types of connectors lie in dimensions and methods of

mechanical coupling. Multimode fiber cables and single-mode fiber cables

require different connectors. SC and LC connectors are the most common

types.

Copper Cabling

For

copper cables supporting 1 Gigabit Ethernet, the Category 5 unshielded

twisted pair (Cat5-UTP) is utilized. With a RJ45 connector on either

end, Cat 5 can support connections of up to 100 meters. Cat5e, an

enhanced version of the Category 5, is the most used Ethernet cabling

today. For lower speed (10 or 100 Mbps) connections, only two of the

four pairs in Cat 5 cables are used. For 1 Gigabit Ethernet, all four

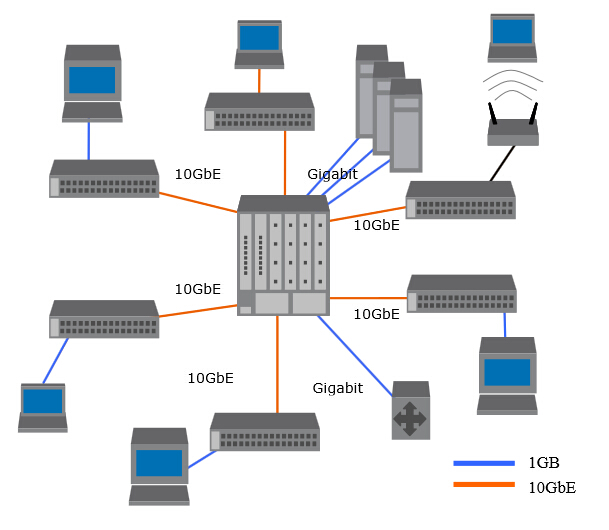

pairs are used. The following picture shows the 1G and 10G application

in an enterprise data center.

10 Gigabit Ethernet Cabling

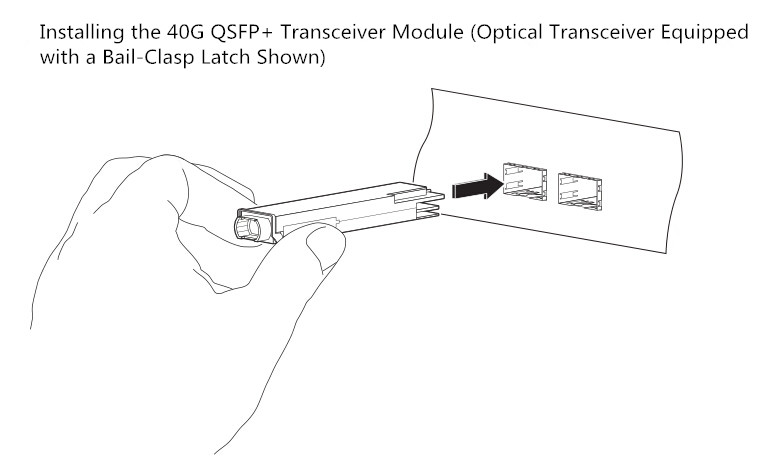

For

10 Gigabit Ethernet cabling, the cabling choices are nearly the same

with the 1 Gigabit Ethernet. The fiber options are very similar. The

transceivers are somewhat different.

Fiber Cabling

An

enhanced version of the SFP transceivers was standardized for use with

10 Gigabit Ethernet and named SFP+ (enhanced small form factor

pluggable). SFP+ has the same mechanical characteristics as the SFP

transceiver. It is capable of supporting the higher speed—10 Gbps.

Besides SFP+ transceiver, XFP (10 Gigabit small form factor pluggable)

transceiver also can support 10 Gigabit Ethernet. Compared with XFP, the

SFP+ has smaller form factor allowing for much more dense packaging of

ports on switches. Moreover, the direct attach copper cable, supporting

10Gbps Ethernet data transmission, has two SFP+ connectors on both end.

This 10G direct attach copper cable like Cisco SFP-H10GB-CU5M

supports transmission distance up to 12-15 meters, which is often more

than enough for interconnecting systems in racks in data centers. With

these two capabilities, SFP+ has become the predominant 10 Gigabit

Ethernet connector type.

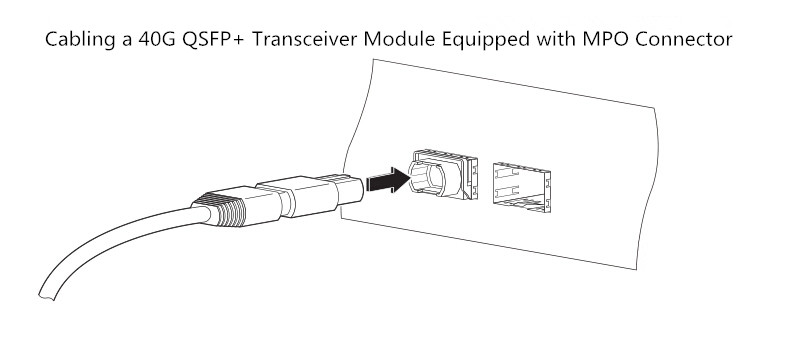

For

10 Gigabit Ethernet fiber connections, the same optical fiber as 1

Gigabit Ethernet is used. The short range fiber cables can support

connections of up to 300 meters and long range fiber cables can support

connections of up to 2 kilometers. Besides these two, a new option is

also available—extended range (for connections of up to 10 kilometers).

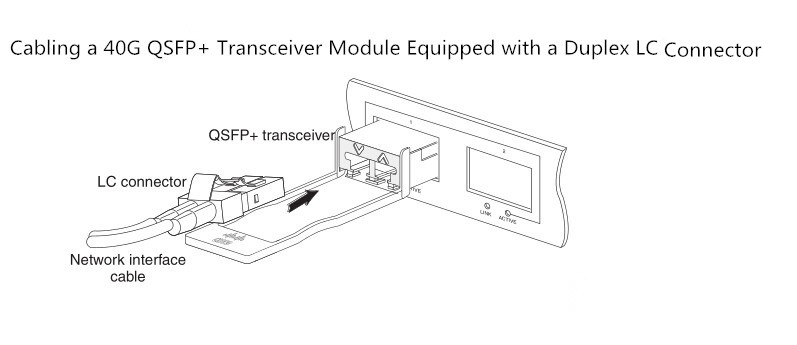

LC

and SC are also the common connector types. Note that these cables can

be connected to either XFP or SFP+ transceivers. The connector type

defines the mechanical specifications of the fiber-to-transceiver

interface. Thus, one could have a XFP transceiver on one end of a 10G

Ethernet fiber cable and a SFP+ transceiver on the other end. As long as

the cable type and connector type match, there is no problem.

Copper Cabling

For

10 Gigabit Ethernet cabling, the standards body determined that even

the enhanced Cat5e UTP traditional Ethernet cable would not be able to

carry the signal reliably for any significant distance. So a new

specification, still using RJ45 connectors, was introduced and named

10GBASE-T. This calls for a 4-wire twisted pair cable with even more

stringent limitations on cross-talk. It is called Cat 6a. 10GBASE-T

cables for up to 100 meters are supported.

Summary

For

1 Gigabit Ethernet connection, SFP transceiver, fiber optic cables and

copper cables are the choices. For 10 Gigabit Ethernet connection, 10G

SFP+, 10G XFP, optical fiber cables as well as copper cables are able to

meet the requirements. Fiberstore, a professional company in the field

of optical network devices and interconnection, supplies various fiber

optic transceivers, fiber optic cables and copper cables. Lots of the

fiber optic products, such as SFP-10G-ER SFP+, have large inventory and low price. For more detailed information about us, please visit www.fs.com.

Article source: www.fiberopticshare.com