Why Migrate to 40G

With

the quick development in data center, cabling infrastructures should

provide manageability, flexibility and reliability. Deployment of

optical connectivity solutions enables for an infrastructure meeting

these requirements for current applications and data rates. Scalability

is another key factor that needs to consider when choosing the type of

optical connectivity. It refers to not only the physical expansion of

the data center with respect to additional servers, switches or storage

devices, but to the scalability of the infrastructure to support a

migration path for increasing data rates. As technology evolves and

standards are completed to define data rates such as 40G/100G, Fibre

Channel (32G and beyond) and InfiniBand (40G and beyond), the cabling

infrastructures installed today need to provide scalability to

accommodate the need for more bandwidth in support of future

applications. Moreover, current data rates cannot meet the needs of the

future with the rising demand to support high-bandwidth applications.

40G technologies and standards, however, can support future networking

requirements. Thus, a migration to 40G is required.

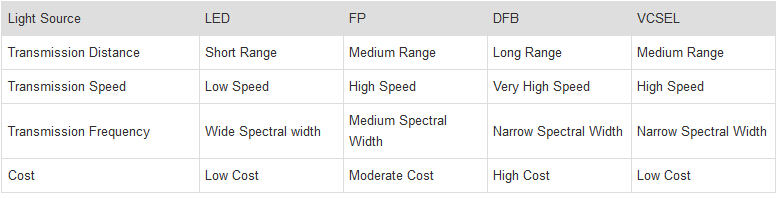

40 Gigabit Ethernet Standard

Ratified

in June 2010, 802.3ba standard provides a guidance for 40G transmission

with multimode and single-mode fibers. And this standard does not have

guidance for Cat UTP/STP copper cable. OM3 and OM4 are the only

multimode fibers included in the standard. Due to the 850nm VCSEL

modulation limits, multimode fibers utilize parallel optics transmission

instead of serial transmission. Single-mode fiber guidance utilizes

duplex fiber WDM (wavelength-division multiplexing) serial transmission.

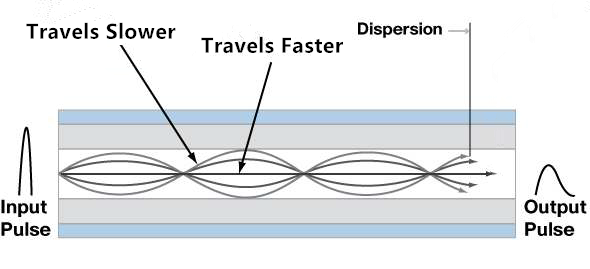

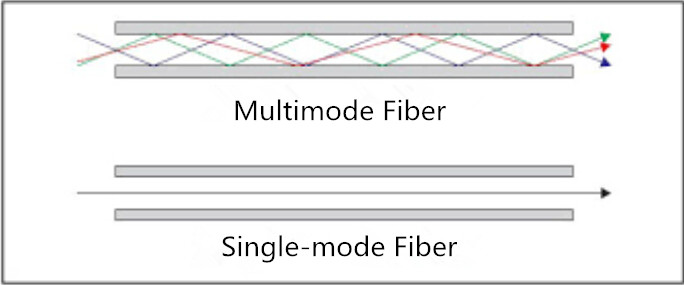

Compared

to single-mode fiber, multimode fiber offers a significant value

proposition for short length interconnects in the data center. Unlike

traditional serial transmission, parallel optics transmission utilizes

an optic module interface where data is simultaneously transmitted and

received over multimode fibers. The 40GBASE-SR4 supports 4 x 10G on four fibers per direction.

Cabling Performance Requirements for OM3/OM4

When

evaluating the performance needed for the OM3 and OM4 cabling

infrastructure, the following criteria should be considered. Each of the

criteria would have an impact on the cabling infrastructure’s ability

to meet the standard’s transmission distance of 100 meters over OM3

fiber and 150 meters over OM4 fiber.

Bandwidth is the primary criteria. OM3 and OM4 fibers

are optimized for 850nm transmission and have a minimum 2000 MHz∙km and

4700 MHz∙km effective modal bandwidth (EMB). Fiber EMB measurement

techniques are utilized today. The minimum EMBc (Effective Modal

Bandwidth calculate) method combines the properties of both the source

and fiber. With a connectivity solution using OM3 and OM4 fibers that

have been measured using the minEMBc technique, the optical

infrastructure deployed in the data center will meet the performance

criteria set forth by IEEE for bandwidth.

Insertion

loss is a critical performance parameter in current data center cabling

deployments. Total connector loss within a system channel impacts the

ability to operate over the maximum supportable distance for a given

data rate. The supportable distance at data rate decreases with total

connector loss increasing. The 40G standard specifies the OM3 fiber to a

100m distance with a maximum channel loss of 1.9 dB, which includes a

1.5 dB total connector loss budget. OM4 fiber is specified to a 150m

distance with a maximum channel loss of 1.5 dB, which includes a 1.0 dB

total connector loss budget. The maximum cable fiber attenuation is 3.5

dB/km at 850 nm. So the insertion loss specifications of connectivity

components should be evaluated when designing data center cabling

infrastructures. With low-loss connectivity components, maximum

flexibility can be achieved with the ability to introduce multiple connector matings into the connectivity link.

flexibility can be achieved with the ability to introduce multiple connector matings into the connectivity link.

Summary

Cabling

deployed in the data center today must be selected to provide support

of data rate applications of the future. To achieve this purpose, OM3 or

OM4 is a must. They provide the highest performance for today’s needs.

With 850nm EMB of 2000 MHz∙km and 4700 MHz∙km, the fibers provide the

extended reach required for structured cabling installations in the data

center. Except the performance requirements, the choice in physical

connectivity is also important. Utilizing MTP-based connectivity in

today’s installations provides ways to migrate to multifiber parallel

optic interface when needed. Therefore, MTP-based connectivity using OM3

and OM4 fiber is the ideal solution in the data center. It can be

installed for use in today’s applications, while providing an easy

migration path to future higher speed technologies.

Article source: www.fiberopticshare.com/data-center-40g-migration-with-om3-and-om4-optical-connectivity.html