Fiber Optic Splicing Basis

It

is vital for any company or fiber optic technician involved in

telecommunications to grasp knowledge of fiber optic splicing methods.

Fiber optic splicing refers to joining two fiber optic cables together.

It can result in lower light loss and back reflection. Two methods of

fiber optic splicing are available: fusion splicing and mechanical

splicing. Which technique best fits your economic and performance

objectives? Keep reading the following statement and find the answer.

Fusion Splicing vs. Mechanical Splicing

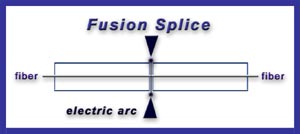

Fusion

splicing is an optical junction of two optical fibers by permanently

welding them together with heat generated by an electronic arc (called

arc fusion). It is the most widely used method of splicing because it

provides least reflectance and lowest loss, as well as providing the

strongest and most reliable joint between two fibers.

Fusion splicing steps:

- Prepare the fiber: strip the protective coatings, jackets, tubes, strength members, and leave only the bare fiber showing. Pay attention to cleanliness.

- Cleave the fiber: using a good fiber optic cleaver here is essential to a successful fusion splice. The cleaved end must be mirror-smooth and perpendicular to the fiber axis to obtain a proper splice.

- Fuse the fiber: alignment and heating are the two steps within this step. Alignment can be automatic or manual depending upon the equipment you have. Once the fusion splicer unit are properly aligned, then you can use an electrical arc to melt the fibers and permanently weld the two fiber ends together.

- Protect the fiber: protecting the fiber from bending and tensile forces will ensure the splice not break during normal handling. Using heat shrink tubing, silicone gel and/or mechanical crimp protectors will keep the splice protected from outside elements and breakage.

Aligning

and holding in place by a self-contained assembly, a mechanical splice

is a junction of two or more optical fibers. Not permanently joined, the

fibers are just precisely held together so that light can pass from one

to another.

Mechanical splicing steps:

- Prepare the fiber: same with the step of fusion splicing.

- Cleave the fiber: the process is identical to the cleaving for fusion splicing.

- Mechanically join the fibers: simply position the fiber ends together inside the mechanical splice unit. The index matching gel inside the mechanical splice apparatus will help couple the light from one fiber end to the other.

- Protect the fiber: the completed mechanical splice will provide its own protection for the splice.

Tips for Better Splicing

- Clean your splicing tools thoroughly and frequently.

- Operate and maintain your cleaver properly.

- For fusion splicing, the fusion parameters must be adjusted minimally and methodically.

Which Method Is Better?

Cost

and performance are the two deciding factors for choosing one method

over the other. Mechanical splicing has a low initial investment ($1,000

- $2,000) but costs more per splice ($12-$40 each). Fusion splicing has

lower cost per splice ($0.50 - $1.50 each) but higher initial

investment ($15,000 - $50,000). As for the performance, fusion splicing

produces lower loss and less back reflection than mechanical splicing.

Fusion splices are primarily used with single-mode fiber, while

mechanical splices work with both single-mode and multimode fiber.

Conclusion

To

sum up, the two fiber optic splicing methods have its own advantages.

Fusion splicing is invested for long haul single-mode networks, while

mechanical splicing is used for shorter local cable runs. For better

fiber optic splicing, besides the above splicing steps, high-quality

fiber optic splicing tools are also essential, such as fusion splicers,

fiber optic cleavers, etc. After all, good methods and excellent tools

will produce the best performance.